About Pipe Hanger Design Software 2.0

The Pipe Hanger Design Software (PHDS) 2.0 web-based application has a wizard-like interface that helps you design multiple pipe hanger assemblies.

Piping Technology Inc manufactures multiple pipe hangers. PHDS2.0 helps you design the following kinds of pipe hangers.

|

|

|

|

|

Constant load hanger |

Rigid support hanger |

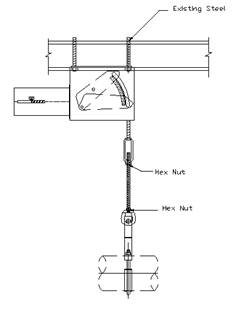

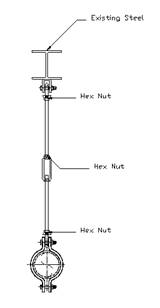

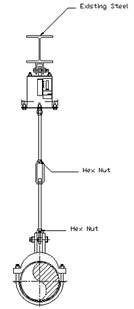

Variable load hanger |

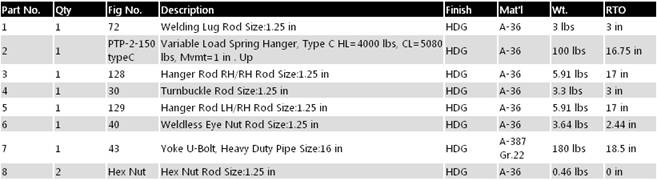

You can use the PHDS2.0 application to design assemblies and generate drawings (.dwg files) on the go. This application generates subcomponents’ specification and also creates a Bill of Materials (BOM), which includes specifications such as materials, rod take-out, and the weight of the individual subcomponents as well as the entire assembly.

|

|

|

Sample Bill of Materials created for a variable load hanger |

You can create multiple assemblies and corresponding drawing files.

To save supports for reuse and to create projects with multiple supports you must register.

Using PHDS2.0

About Pipe Hanger Design Software 2.0

Step

3: Select components of the pipe hanger assembly

Step

4: Specify the pipe support design parameters

Registration

To create a new account:

1) Click Create an account on the home page.

2) Enter a valid Email ID and choose a password.

|

! |

Your password must have at least 6 characters. |

|

|

|

3) Complete the Captcha entry – type the characters that you see in the image in the box below the image.

4) Click Create User.

An email is sent to the Email ID you specified in step 2.

5) Click the link in the email to activate your account.

You can now login to your account.

|

! |

When you login to a new account, you will see a blank page. Click the Create Project button to create a new project. |

Creating a new support

Step 1: Project title page

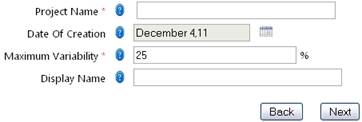

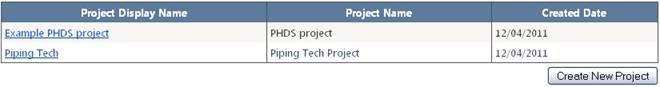

When you click Create New Project on the Projects page, the Project Title page opens.

Specify basic details that will help identify the project.

·

Project

Name

· Date of Creation – You can use the default date, or customize it.

· Maximum Variability – This is the value of (Hot Load - Cold Load)/(Hot Load)

· Display Name – If you don’t specify a value, the project name is used.

Click the Next button to create the project.

|

! |

When you click the Next button, you will see a blank page. Click the Create Support button to create a new support for that project. |

If you have existing projects, you can view them by clicking Projects. You can open and edit an existing project.

Step 2: Create a support

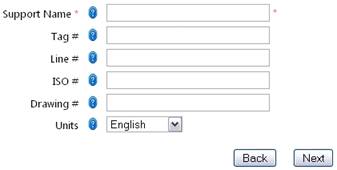

When you click the Create Support button on the Supports page, the Support Details page opens.

Specify basic support details that will help identify the support.

|

! |

At this stage, specifying the Support Name is mandatory; all other fields are optional. If you do not specify the units, the default value is used. |

|

|

|

Click the Next button to create the support.

If you have existing supports, you can view them by clicking Supports. You can open and edit an existing support.

Step 3: Select components of the pipe hanger assembly

When you click the Next button on the Support Details page, the Select Assembly page opens.

Select assembly components starting from the top.

|

! |

It is recommended that you make your selections from top to bottom, since the available options change depending on your previous selection. |

|

|

|

You can create the following types of assemblies:

· Constant Hanger (Horizontal or Vertical Configuration)

Once you select all the components of your assembly, a preview is displayed along with a bill of materials.

|

! |

You can click the links in the Component Name column of the bill of materials to see more details of the selected component. |

|

|

|

Click the Next button to complete the assembly component selection.

Step 4: Specify the pipe support design parameters

When you click the Next button on the Select Assembly page, the Data Input page opens.

Specify the various parameters that define the support. The design parameters differ depending on the type of support you are designing.

Constant Hanger

Piping Technology and Products - Constant Support Hanger catalog

To create a constant hanger, you must specify:

· The load at the point of support, while the plant is in operation (Operating Load).

· The expected movement in the piping system at the point of support (Movement).

· The direction of the movement expected at the point of support (Direction of Travel).

· The total height available for the hanger (elevation).

· The diameter of the pipe for which the hanger is being designed (Pipe Size).

Specifying the Hydrotest Load, the Operating Temperature, and the Insulation

Thickness is optional.

Variable Hanger

Piping Technology and Products -

Variable Support Hanger catalog

To create a variable hanger, you must specify:

· The load at the point of support (Hot Load or Cold Load or both).

· The expected movement in the piping system at the point of support (Movement).

· The direction of the movement expected at the point of support (Direction of Travel).

· The total height available for the hanger (Elevation).

· The diameter of the pipe for which the hanger is being designed (Pipe Size).

Typically specifying either the hot load or the cold load is enough to design the hanger, and specifying both leads to fewer spring selection options.

Specifying the Hydrotest Load, the Operating Temperature, and the Insulation

Thickness is optional.

Rigid Hanger

To create a rigid hanger, you must enter:

· The load at the point of support, while the plant is in operation (Operating Load).

· The total height available for the hanger (Elevation).

· The diameter of the pipe for which the hanger is being designed (Pipe Size).

Rigid hangers have no movement. Consequently,

there is no direction of travel.

Specifying the Hydrotest Load, the Operating Temperature, and the Insulation

Thickness is optional.

Click the Next button to complete the design and generate a drawing file.

Step 5: Generate the drawing

When you click the Next button on the Data Input page, the Design Result page opens.

This page displays an exhaustive summary of the support including a bill of materials, design notes, design data, and a list of assembly sub-components.

You can click the Drawing file link at the beginning of the Summary or click the Generate Drawing button at the bottom of the Design Result page to obtain a drawing file (.dwg file) that you can save on your computer.

Saving your design

You cannot save the project or the support design in the web-based application if you are not logged in. However, you can still design a support, obtain the design summary, and generate a drawing.

When you are logged in, you can

click the Save button (![]() )

at any step in the design process, to save your support design and return to

that step at a later time.

)

at any step in the design process, to save your support design and return to

that step at a later time.

Navigation

It is recommended that you use the Back and Next buttons provided in the PHDS application to navigate the pages instead of the navigation buttons on your browser window.

You can also use the breadcrumbs at the top of the page, to jump from one step to another.

![]()

Glossary

↘

Cold

load

The load at the point of support,

while the plant is in operation.

↘

Direction

of travel

The direction of the movement expected at the point of

support.

↘

Elevation

The total height available for the hanger.

↘

Hot

load

The load at the point of support, while the plant is

in operation.

↘

Hydrotest

load

Hydrotest load on the hanger.

↘

Input

movement

The expected movement in the piping system at the

point of support (Movement).

↘

Insulation

thickness

Insulation

thickness on the pipe.

↘

Maximum

variability

This is the value of (Hot Load – Cold Load)/(Hot

Load).

↘

Operating

load

The load at the point of support, while the plant is

in operation (Hot Load or Cold Load or both).

↘

Operating

temperature

The operating temperature of the hanger.

↘

Pipe

size

The diameter of the pipe for which the hanger is being

designed.

↘ Total Movement

The value of the movement in the piping system after accounting for

over-travel. This parameter is calculated by the PHDS application.